Is your attraction operating at its full design capacity potential?

Key performance indicators, like your capacity utilization metric can help you find out. This is a crucial metric for businesses.

Measuring this allows you to know your optimal capacity utilization and helps you identify your most and least popular listings, as well as which time slots are selling out. It can also bring you insight into your company’s actual level of output (how many tours you’re currently conducting) compared to its maximum potential capacity (how many tours you have the resources to conduct).

In this post, you’ll learn how to use a capacity utilization formula to better understand your true productive capacity and make informed decisions to boost your target profit margins.

- What is capacity utilization?

- How capacity utilization works

- How companies use capacity utilization

- Historical capacity utilization rates

- The key differences between capacity utilization and operational efficiency

- Why should travel and tourism companies care about measuring capacity utilization?

- What’s the simplest capacity utilization formula?

- Additional ways to calculate capacity utilization

- Capacity utilization example for travel companies

- Capacity utilization benchmarks

What is capacity utilization?

Capacity utilization is a measure of a company’s actual output level compared to its potential output level.

A capacity utilization report can, for instance, show you how many of your listings were booked at or above 75% in the last month — and highlight those operating under 25% capacity.

With this information in hand, your attraction could then make informed staffing and pricing decisions to maximize your revenue and profit margins.

This sophisticated pricing and inventory technique is also known as yield management. It was initially pioneered by the airline industry to help maximize revenue per airplane seat.

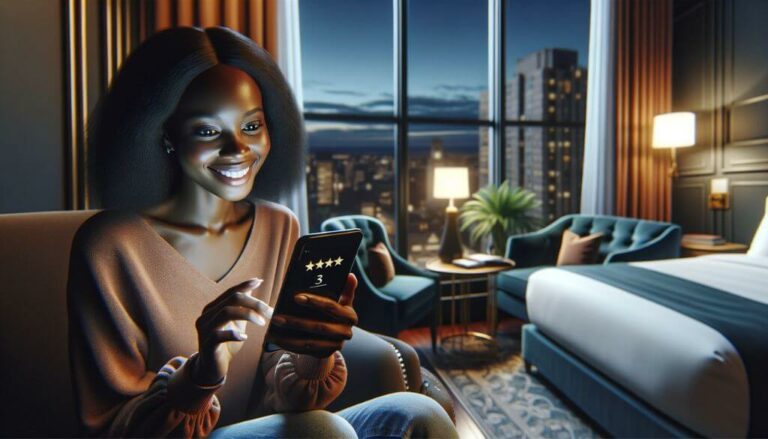

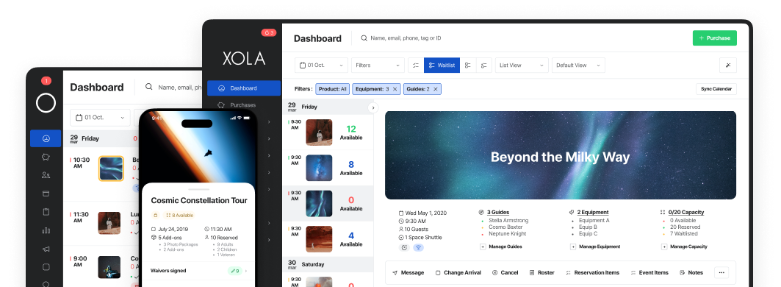

A booking platform like Xola can provide you with a detailed capacity utilization report that breaks down your most popular tours and experiences at any time slot. If you operate an escape room attraction, for instance, you could find out how often your rooms are booked at full capacity.

When you have a good grasp on your inventory, you’re able to better allocate resources like equipment and staff, as well as make smart pricing decisions to boost your revenue.

How capacity utilization works

Capacity utilization quantifies the extent to which your business leverages its resources. It compares your actual production process (and output) to potential production, giving you insights into operational efficiency.

Imagine your tour company operates at a 70% capacity utilization rate. This means 70% of your tours are fully booked, while 30% have room for more guests. This metric helps you pinpoint opportunities to enhance productivity and profitability.

For example, if your popular afternoon city tour consistently books at 90%, but your morning tour lags at 50%, you have a clear indicator to adjust your strategy to be better aligned with market demand. Maybe offering a discount for morning slots or adding more afternoon tours could balance demand and boost overall capacity utilization.

Understanding these patterns allows you to make informed decisions about marketing efforts, staffing levels, and cost structures.

With accurate capacity utilization data, you can optimize resource allocation, ensuring that your staff and equipment are used efficiently. This leads to increased revenue and improved customer satisfaction as you better meet demand.

How companies use capacity utilization

Companies across various industries harness this concept of capacity utilization to drive strategic decisions and optimize their operations. By measuring how effectively they are using their resources, businesses can identify areas for improvement and capitalize on opportunities for growth.

For instance, a hotel chain might analyze its capacity utilization to understand seasonal booking patterns. If they notice that occupancy rates drop significantly during certain months, they can implement targeted marketing campaigns or promotional offers to attract more guests during these periods. This proactive approach helps maintain a steady revenue stream throughout this slower time frame.

Manufacturing plants, on the other hand, utilize capacity utilization to manage physical products and production schedules. If a factory operates at only 60% capacity, it might indicate that there is room to increase the current output without significant additional costs. Conversely, running consistently at 100% maximum output capacity could signal the need for expansion or investment in new equipment to avoid bottlenecks and meet growing demand.

Retailers can also benefit from capacity utilization insights. By tracking the usage of floor space and inventory turnover rates, they can optimize product placement and stock levels. For example, if certain products are consistently selling out while others remain untouched, retailers can adjust their inventory strategies to ensure popular items are always available, boosting sales and customer satisfaction.

Service-based businesses, such as consulting firms or law practices, use capacity utilization to balance workloads among their staff. By analyzing how much time employees spend on billable tasks versus administrative duties, they can improve employee productivity and allocate resources more efficiently.

In all these scenarios, the goal is to achieve an optimal capacity ratio where resources are used efficiently without overstraining them.

Historical capacity utilization rates

Understanding historical capacity utilization rates offers valuable insights into economic trends and business cycles. These rates reflect the extent to which industries and economies have used their productive resources over time, providing a clear picture of periods of growth and recession.

Historically, capacity utilization rates have fluctuated in response to various economic events. For instance, during periods of economic expansion, such as the post-World War II boom, capacity utilization rates often surged as factories and businesses operated at near full capacity to meet rising demand. Conversely, during economic downturns, like the Great Recession of 2008-2009, these rates plummeted as demand fell and production slowed.

In the manufacturing sector, capacity utilization has been a key indicator of capitalist economies’ health. In the mid-20th century, manufacturing capacity utilization in the North American economy often hovered around 85-90%. This high rate indicated robust industrial activity and a strong economy. However, during slow economic cycles, such as the oil crises of the 1970s and the early 1980s recession, utilization rates dropped significantly, reflecting decreased industrial levels of output and economic challenges.

The services sector, which has grown in importance over the decades, also shows variable capacity utilization trends. Service industries, like hospitality and transportation, experience cyclical fluctuations in utilization rates. For example, airlines and hotels typically see higher utilization rates during peak travel seasons and lower rates during off-peak times. Historical data from these industries help businesses anticipate demand and plan accordingly.

Analyzing historical capacity utilization rates also helps policymakers and economists make informed decisions. High utilization rates can signal potential inflationary pressures, prompting central banks to consider tightening monetary policy. Conversely, low utilization rates might indicate underused resources and economic slack, leading to measures aimed at stimulating growth.

The key differences between capacity utilization and operational efficiency

As you now know, capacity utilization is an advanced inventory and pricing technique used to boost your profit margins.

It’s the relationship between potential maximum output and the actual number of tours or tickets you’re selling.

Measuring your capacity utilization can help you make decisions about your resources — such as knowing when to hire new staff or adjusting tour guide schedules to meet tour demands. Let’s say you run a food tour company and find that your capacity is reaching 100%. Your tours are sold out, and your guides are fully booked.

To accommodate additional guests, you’d likely need to add a new time slot and hire a new guide.

Operational efficiency, on the other hand, is the relationship between an attraction’s output and input.

It refers to completing a task with fewer resources, whether that be time, equipment, staff, or capital. This is known as a business’ resource utilization. An attraction that’s able to decrease operational costs while increasing its output level — such as hosting more guests — will see a boost in its operational efficiency.

For example, if you run a museum, one way to increase your operational efficiency is to ensure you’re making the best use of your current staff.

After studying employee schedules, you realize that you have 15 staff members working on your slowest days, while the same number of employees are working over the weekends. To boost your operational efficiency, you decide to decrease the number of employees working during the week.

Instead, you shift one or two of them to Saturday and Sunday to assist with your current staff. As a result, you’re now using your resources more efficiently.

Why should travel and tourism companies care about measuring capacity utilization?

Can you name your most popular tours or experiences off the top of your head? Now, can you tell us how often those tours or experiences are fully booked? Xola’s capacity utilization report can help you figure this out.

Measuring your capacity utilization can tell you how many of your listings were booked at or above 75% capacity in the last month. Perhaps more importantly, it can also show you how many were operating under 25% capacity.

This means you can track how specific listings, tours, or experiences are faring over time. You can then make any necessary adjustments to pricing, staffing, or resources based on that data.

For example, a zoo operator might run a capacity utilization report and find that its afternoon shifts are running at near-full capacity, while no one is visiting in the morning.

After finding this out, you decide to open later in the day and keep the zoo open into the evening. You might also launch a marketing campaign focused on driving more visits during your slow hours.

Another benefit of measuring capacity utilization is being able to change your prices to match ongoing fluctuations in supply and demand.

For example, you might offer a discounted rate for the morning slots every time someone lands on your website. This Lightning Deal might persuade more people to book the less desirable time slot so that you’re operating at full capacity.

What’s the simplest capacity utilization formula?

The easiest way to find your capacity utilization rate is to divide the actual capacity of your tours by the total capacity, then multiply by 100.

Capacity Utilization Rate Formula: (Actual Capacity Being Used / Total Capacity) x 100

Any number under 100% indicates that your attraction is operating at less than its full potential. Below, we’ll talk through ideal capacity utilization rates based on industry benchmarks.

Additional ways to calculate capacity utilization

Let’s take a look at a few different ways you can measure capacity utilization.

Ideal Utilization Rate

Many businesses want to find the best capitalization rate for their particular company. While some look to industry benchmarks, others calculate an ideal rate based on business costs, pricing, and profit.

With this formula, you can better determine the ideal utilization rate for your company to reach its desired profit margin.

Ideal Utilization Rate Formula: ((Resource costs + overhead + profit margin) / Potential capacity x Billable rate) x 100.

Let’s say you run an escape game company. Your employee costs you $50,000 per year, and the overhead costs for that employee amount to $500. The billable rate for this employee is $55 an hour, and they have the capacity to work 25 hours per week for 48 working weeks per year. Meanwhile, your ideal profit margin is 8%. What’s your ideal utilization rate?

($50,000 + $500 + $4,040) / (1,200 hours x $55 an hour) x 100 = 82.6%

Therefore, your ideal utilization rate would be 82.6%.

Calculating machine capacity utilization

Machine capacity utilization is a manufacturing metric that shows how well a company’s machinery is being utilized. It can be used to identify problems in a manufacturer’s production line, such as having too many or too few working machines.

You can calculate it by finding the actual output of a machine and dividing it by its potential output, then multiplying by 100.

For example, if a manufacturer’s performance is low, it might look into whether one of its machines needs to undergo maintenance.

Calculating occupancy and utilization

Calculating your employee utilization rate can help you see how well your current staff is being utilized. You’ll then be able to determine if hiring new staff members is necessary.

- Calculate the number of hours an employee is on the clock during a standard week.

- Calculate how many hours the employee is actually working, such as how many hours a tour guide is actually giving tours.

- Divide the hours worked by the total hours the employee was available during the week.

Capacity utilization example for travel companies

Let’s say you offer extreme water sports tours. To maximize your revenue and ensure an efficient operating rate, you need to closely monitor your utilization of resources, including labor costs.

Over a specific period of time, you track the booking rates for all of your various tours. For example, during the peak summer season, you aim to operate at an 85% target capacity utilization rate. This means that 85% of your available tour slots are booked. Achieving this target helps spread the average costs of operations across a larger number of customers, reducing the cost per unit.

This high rate indicates that customer demands are being met efficiently, and the fixed costs of running the tour are well distributed.

However, during the off-peak winter months, you might experience a drop in bookings. If the average number of guests per trip falls to 50, the capacity utilization rate drops to 50%. This lower rate means the cost per unit increases, as the fixed costs, including costs per employee, are now spread across fewer customers. So, you might want to address this by offering promotions or discounts to attract more bookings and improve your capacity utilisation rate.

By analyzing capacity utilization over different time periods, you can make smart decisions about pricing and staffing. For instance, you might want excess capacity and hire additional guides during high-demand periods to ensure high levels of customer satisfaction and reduce wait times. Conversely, during low-demand periods, they might reduce staff hours to manage costs effectively.

Capacity utilization benchmarks

While it varies by industry, most companies and economies strive for capacity utilization of 85% to 100%. Headcount or employee utilization rates should be around 85% to 90%, according to HubSpot.

***

In conclusion, measuring your capacity utilization rate can help your attraction reach its full potential.

You can not only leverage Xola’s capitalization report to sell out your tours but also maximize your profits.

If you are already a Xola customer, here is how you can access this report..

Not a customer? Watch a demo here.